AGGREGATE

WHAT IS AGGREGATE

Gluey Aggregates stands as a prominent supplier of high-quality granular materials, such as sand, gravel, and crushed stone, which are fundamental components in the construction industry. Our meticulously blended and cured aggregates result in a robust and enduring material, essential for a myriad of construction applications.

As a distinguished subsidiary within the Gluey Aggregates Group, Gluey Aggregates (Pvt) Ltd. assumes a crucial role in providing top-tier aggregates to the construction sector. Situated in Dompe

WHAT IS MANUFACTURED SAND ?

Sand plays a fundamental role in construction, serving as a crucial ingredient in every phase of the building process, from the foundation to the finishing touches. With the construction industry utilizing nearly 2 million m3 of sand annually for concrete alone, the demand for this essential resource is substantial. Traditionally, sand has been predominantly sourced from river beds throughout the country. However, the escalating demand for sand has led to the alarming practice of unlawful and unregulated sand mining, resulting in significant environmental repercussions.

HOW IS M-SAND PRODUCED ?

M-sand, or Manufactured Sand, is meticulously crafted through the crushing of specific varieties of granite, tailored to attain the essential characteristics needed for concrete production. The production process involves an additional level of value addition after the initial crushing, where Crushed Sand undergoes further crushing and meticulous washing to yield the final high-quality product – Manufactured Sand.

As a distinguished subsidiary within the Gluey Aggregates Group, Gluey Aggregates (Pvt) Ltd. assumes a crucial role in providing top-tier aggregates to the construction sector. Situated in Dompe

WHY MANUFACTURED SAND ?

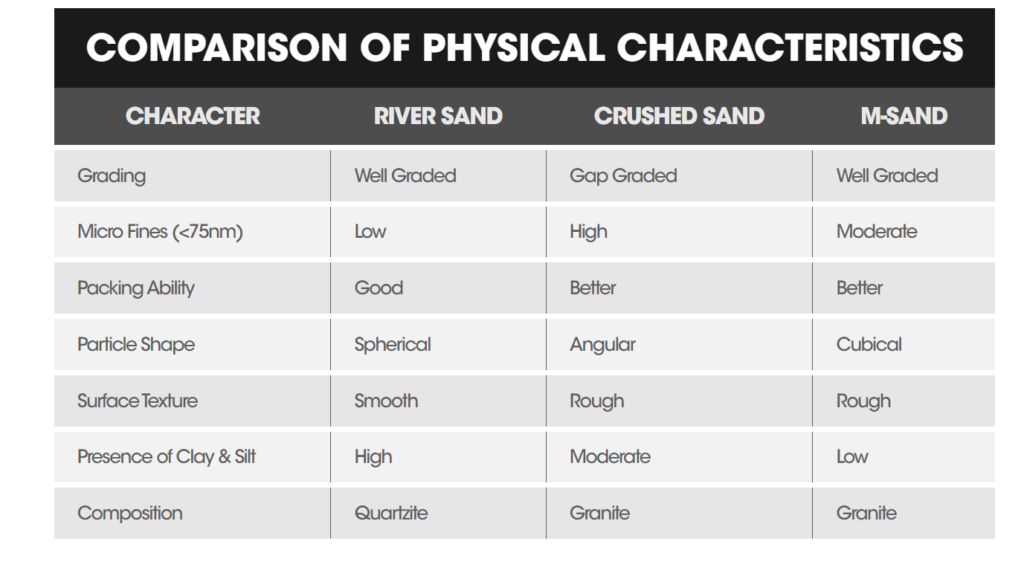

In contrast to river sand or sea sand, Gluesy M-sand emerges as a superior choice, devoid of impurities such as clay, shell, limestone particles, and other organic and chemical compounds that could compromise the strength and quality of concrete. Crafted by crushing high-quality granite, Gluesy M-sand significantly enhances the durability and strength of concrete, demonstrating resilience against corrosion and chemical attacks.

The technical manufacturing process of Gluesy M-sand imparts a distinctive rough cubical shape to the sand particles, complemented by rounded-off edges. This unique characteristic facilitates the creation of stronger bonds between the cement and the coarse aggregate, contributing to the overall robustness of the concrete structure. Moreover, the advanced technology employed in the manufacturing process allows for precise grading of the M-sand grains, ensuring a specific size distribution is maintained.

WHAT ARE THE DRIVING FACTORS FOR M-SAND ?

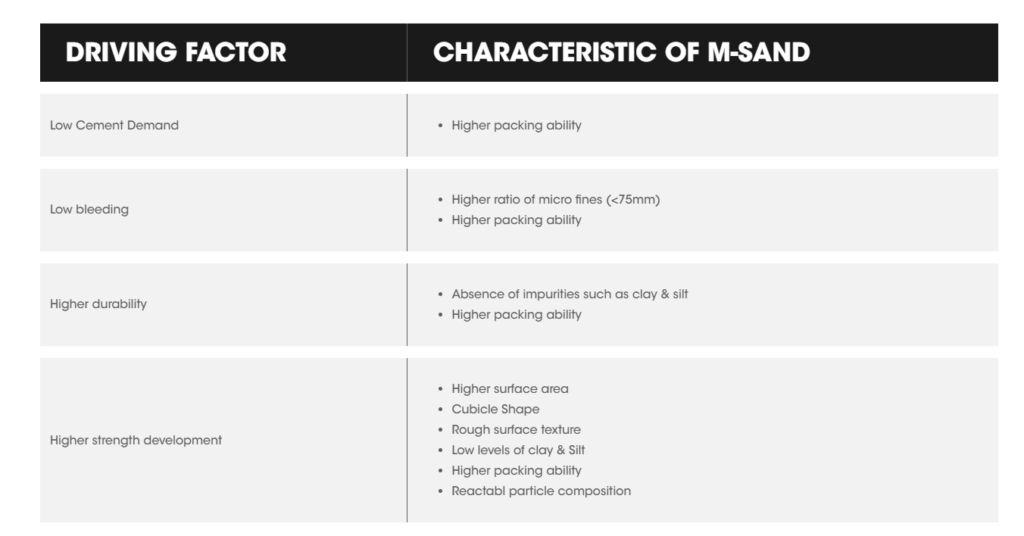

As previously discussed, Gluesy M-sand stands out in comparison to River Sand and Crushed Sand, requiring a reduced volume of cement to achieve equivalent strength in concrete, owing to its superior packing ability. This, coupled with higher micro fines content, effectively minimizes bleeding in the concrete—a critical factor influencing durability. The low impurity levels further contribute to the overall durability of the concrete. The combination of these characteristics, along with the rough surface area and cubical shape of M-sand, leads to enhanced concrete strength.

Despite these positive attributes, there are a few considerations to address when working with M-sand. It has a higher demand for water, and the rough cubical shape of particles can result in poor workability. Additionally, there is an increased need for superplasticizers to aid in setting time. However, to overcome these challenges, the use of a suitable admixture is recommended. This not only improves workability but also enhances compressive strength, ensuring that the advantages of Gluesy M-sand are maximized in construction applications.

GLUEY SUPERSANT

GLUEY SUPERSAND is meticulously manufactured under stringent quality standards to ensure the excellence of GLUEY SUPERMIX Ready Mix Concrete provided to our valued customers. Leveraging our unparalleled vertical integration capability, Gluey allows us to standardize and meticulously control the composition of particle sizes in both Manufactured Sand and coarse aggregates used in creating GLUEY SUPERMIX. This unique capability enables us to optimize mix designs, delivering a diverse range of concrete solutions tailored to meet specific customer requirements.